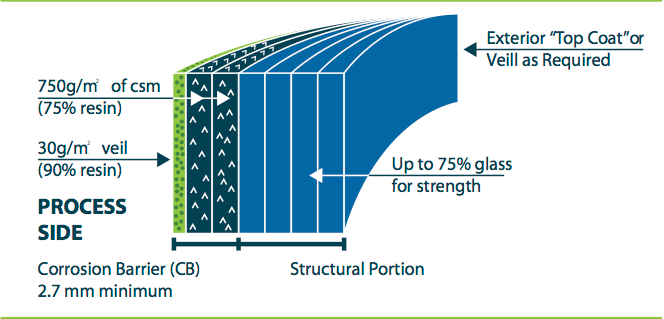

FRP is a composite material made of a polymer matrix reinforced with fibres, usually glass fibres. The polymer provides excellent chemical resistance while the fibres provide the structural integrity. Depending of the resin type and the glass to resin ratio the material properties for every individual structural layer can be optimised for corrosion resistance and physical strength.

Figure 1: Typical Corrosion Resistant FRP Laminate Construction

For most wet applications, the maximum operating temperature is 100°C (212°F) with excursions up to 120°C (248°F). Dry environments can operate at 177°C (350°F) with excursions up to 204°C (400°F). Because not all resins are suitable for processes that have thermal cycling or high temperature excursions, it is important to consult and obtain warranties from the resin manufacturer when designing for these applications.

As with all construction materials in corrosive environments, FRP has specific design and fabrication requirements which will ensure its success. These requirements consist of the following: